#scada programming

Explore tagged Tumblr posts

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Best PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, we provide the Best PLC Training In Pune. Our institute is known for its advanced courses and modern facilities. Whether you are a beginner or an experienced professional looking to enhance your skills. We offer customized programs to meet your needs.

Firstly, Perfecto Robotics Institute offers training led by industry experts.

Students actively participate in practical exercises, which develop a thorough understanding of PLC systems. Additionally, our instructors emphasize real-world applications, preparing graduates for the challenges of various technological environments.

What Are PLC Training?

Prepares technicians to take full advantage of vendor training on specific equipment. We covers the basic operating principles of all PLCs, their inputs and outputs, programming, maintenance, and networking. This course has no prerequisites.

What is PLC?

PLC stands for Programmable Logic Control.

PLC is a type of industrialized computer that is responsible for controlling various functions, including inputs, outputs, and central processing units.

What are examples of PLCs?

Manufacturing

Oil and Gas

Automotive

Food and Beverage

Utilities

Building Automation

Pharmaceuticals

What are the main components of PLC?

CPU (Central Processing Unit)

Input / Output (I/O) Modules

Power Supply

Memory

Programming Terminal or Computer

Communication Ports

Expansion Modules

Why is PLC used?

increased dependability

Safety

Real-time Tracking

Able to work 365 days a year 24/7

Repeatability

Reduced energy consumption

Space requirements are reduced.

increased user experience flexibility

You can handle various devices at the same time.

Increased machine connectivity and procedure automation

Manufacturing processes will be increased.

Reduced operational costs

0 notes

Text

Elevate your automation game with CalCon & KNEO Automation!

🔹 PLC, HMI, SCADA Software Development: Unlock the full potential of your industrial processes with our cutting-edge software solutions. 🔹 Empower your team with seamless control, real-time monitoring, and data-driven insights. 🔹 Maximize efficiency, reduce downtime, and enhance productivity with our expertly crafted PLC programs. 🔹 Seamlessly integrate HMI and SCADA systems for intuitive and user-friendly control interfaces. 🔹 Stay ahead of the competition with our advanced robotics integration and virtual commissioning solutions

For more details https://bit.ly/4eR6rQn

Transform Industrial Automation with CalCon & KNEO: PLC, HMI, SCADA Solutions & More!

0 notes

Text

Which language is best for PLC?

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone of countless manufacturing processes. These versatile devices are the driving force behind the automation of various tasks, from simple machinery control to complex manufacturing processes. However, when it comes to choosing the best programming language for PLCs, beginners often find themselves at a crossroads. In this article, we'll delve into the key factors to consider when selecting a programming language for PLC and explore some popular options to help you make an informed decision.

Importance of PLC Training and Courses: Before delving into the PLC programming languages, it's crucial to emphasize the significance of PLC training and courses. As the demand for skilled automation professionals continues to rise, enrolling in a reputable corporate training institute that offers comprehensive PLC training becomes a stepping stone towards a successful career. PLC courses, especially those tailored for beginners, provide a solid foundation in PLC programming, troubleshooting, and design, enabling individuals to tackle real-world automation challenges.

Selecting the Ideal Programming Language: The choice of programming language for PLC largely depends on the specific application, hardware compatibility, and personal preferences. Let's take a look at some commonly used programming languages in the PLC landscape:

Ladder Logic (LD): As one of the oldest and most widely used languages in PLC programming, Ladder Logic offers a graphical representation of control circuits. Its resemblance to electrical relay diagrams makes it an excellent choice for individuals with a background in electrical engineering. PLC programming courses for beginners often start with Ladder Logic due to its user-friendly nature.

Structured Text (ST): For those with a programming background, Structured Text provides a text-based language resembling traditional programming languages. It offers more advanced control and data manipulation capabilities, making it suitable for complex applications. ST is commonly used in PLC programming courses for those who want to dive deeper into automation.

Function Block Diagram (FBD): FBD is another graphical language that allows users to create complex functions by combining various function blocks. It's ideal for modular design and is often used in conjunction with other languages.

Sequential Function Chart (SFC): SFC focuses on the sequential control of processes, making it suitable for applications where the order of operations is critical. It's commonly used in industries where processes follow a specific sequence, such as batch processing.

Instruction List (IL): IL is a low-level language resembling assembly language. While it may not be the first choice for beginners, it offers precise control over the PLC's operations and is often used for optimizing code.

PLC SCADA Training Institute and Beyond: As you embark on your journey to master PLC programming, consider enrolling in a reputable PLC SCADA training institute. Such institutes offer specialized courses that cover not only PLC programming but also SCADA (Supervisory Control and Data Acquisition) systems, HMI (Human-Machine Interface) design, and industrial communication protocols. This comprehensive training equips you with the skills needed to design, implement, and maintain sophisticated industrial automation systems.

Conclusion: In the dynamic world of industrial automation, choosing the right programming language for PLC is a decision that shouldn't be taken lightly. Factors such as application requirements, hardware compatibility, and personal familiarity play a crucial role. Whether you opt for the user-friendly Ladder Logic or the more versatile Structured Text, embarking on a PLC programming course for beginners is the first step towards a rewarding career in automation. DIAC in noida, is one of the best industrial automation institutes in Delhi NCR, your right step makes a huge change in your journey of automation. Remember, the journey doesn't end with PLC – exploring additional aspects like SCADA and HMI through specialized training institutes can further enhance your skill set and open doors to exciting opportunities in the world of industrial automation.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#plc programming courses for beginners

0 notes

Text

What You Can Specialize in and Pursue After B.Tech in Electrical and Electronics Engineering

Pursuing a B.Tech in Electrical and Electronics Engineering (EEE) opens up a world of opportunities in one of the most versatile and evergreen branches of engineering. From core electrical roles to cutting-edge electronics, automation, and IT sectors, the scope for growth and specialization is vast. If you're looking for a b tech electrical and electronics engineering college in UP, it’s important to understand not just the curriculum but also the career avenues and industry demands linked to your degree.

Why Choose Electrical and Electronics Engineering?

EEE is a discipline that merges two major areas of engineering—Electrical Engineering, which deals with the study and application of electricity and electromagnetism, and Electronics Engineering, which focuses on circuits, devices, and integrated systems. This powerful combination equips students with a diverse skill set applicable in numerous industries.

When you choose a reputed btech college in UP that offers specialization in EEE, you benefit from practical exposure, strong technical foundations, and placement support that align with your career goals.

Popular Specializations After B.Tech in EEE

After graduating from a b tech electrical and electronics engineering college in UP, students can either pursue higher education or dive straight into industry roles. Some choose to specialize further by opting for M.Tech, MS, or professional certifications. Here are some of the popular specializations:

1. Power Systems Engineering

This specialization focuses on generation, transmission, and distribution of electric power. Students can work with power generation companies, government utilities, or in energy infrastructure projects.

2. Control and Automation

With the rise of smart factories and Industry 4.0, automation is booming. This field deals with control systems, robotics, PLCs, and SCADA systems, offering roles in manufacturing and tech-driven industries.

3. Embedded Systems and VLSI Design

Ideal for students interested in microelectronics, embedded system design, and chip manufacturing. This is a great path if you're inclined toward product design and development.

4. Renewable Energy

As the world shifts toward clean energy, specialists in solar, wind, and hybrid systems are in demand. A focus on renewable energy systems prepares you for a sustainable engineering future.

5. Telecommunication Systems

This specialization covers wireless communication, optical fiber technologies, and network systems—ideal for roles in telecom giants and network companies.

Career Opportunities After B.Tech in EEE

Graduating from a top btech college in UP with a degree in EEE means you’ll have access to roles across various sectors, including:

Electrical Engineer in power plants, utilities, and infrastructure projects

Electronics Engineer in semiconductor and electronics manufacturing

Automation Engineer in industries using robotics and automated systems

Embedded Systems Developer in hardware and IoT product companies

Telecom Engineer in network operations, 5G rollout, and telecom services

Design Engineer for electrical layouts, PCB design, and embedded systems

Government Jobs through GATE, UPSC, and public sector undertakings (PSUs)

You can also explore careers in research organizations, startups, and IT companies that require electronics and hardware expertise.

Choosing the Right College Matters

To unlock these opportunities, choosing the right college is crucial. A good b tech electrical and electronics engineering college in UP not only provides academic knowledge but also offers hands-on lab training, industry exposure, internships, and placement assistance.

When you study at one of the top btech colleges in UP, you benefit from a strong alumni network, active campus recruitments, skill development programs, and access to modern research facilities. These factors significantly boost your confidence and employability in competitive job markets.

Conclusion

B.Tech in Electrical and Electronics Engineering is more than just a degree—it's a gateway to diverse, dynamic, and future-focused careers. Whether you want to innovate in electronics, lead energy solutions, or automate the next industrial revolution, your journey begins with choosing the right btech college in UP that aligns with your goals. So take the first step today—explore the top btech colleges in UP and find the EEE program that powers your passion and profession.

0 notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Video

youtube

SCADA Applications in Water Treatment #scada #tech #shorts #industrial #...

Asteam Techno Solutions Pvt. Ltd. is AVEVA (Formerly Wonderware) Registered System Integrator providing sale/service/support and execute the HMI/SCADA, Historian/MES Solutions to End-user & OEM/System Integrator community for their diverse needs Asteam Techno Solutions Pvt. Ltd. is a leading and preferred solution provider for all kind of Industrial Automation requirements in the field of Process and Power Automation. Established in 2017, Asteam Techno Solutions is an ISO 9001: 2015 certified company, having its Design, Manufacturing & Repair facility located in Surat, Gujarat, India and provides total integration under one roof.

#youtube#scada#scadaprogramming#plc#plc programming#plc automation#industry#industrial#automation#youtumblr#tumblr

2 notes

·

View notes

Text

Rattan Industrial – A Leading Distillery Plant Manufacturer Empowering India’s Alcohol Production Industry

In the heart of India’s growing spirits and ethanol industry lies the need for robust, efficient, and scalable distillery solutions. Whether producing potable alcohol or fuel-grade ethanol, manufacturers require a plant setup that meets regulatory standards, ensures maximum yield, and operates with minimal downtime. This is where Rattan Industrial India Pvt. Ltd. stands out as a trusted distillery plant manufacturer delivering end-to-end solutions for alcohol production.

Why Choose Rattan Industrial for Your Distillery Plant?

With decades of experience and a deep understanding of the distillation process, Rattan Industrial provides complete turnkey distillery solutions — from raw material handling to final alcohol storage. The company supports clients across India and overseas with the latest technologies in fermentation, distillation, and waste management.

Here’s what makes Rattan Industrial a preferred partner in distillery plant manufacturing:

1. Complete Turnkey Projects Rattan Industrial designs, fabricates, and installs entire distillery plants including:

Molasses or grain handling systems

Fermentation vessels and yeast propagation units

Multi-pressure distillation columns

Dehydration units for fuel-grade ethanol

Spent wash handling and Zero Liquid Discharge (ZLD) systems

Stainless steel storage tanks and bottling lines

Every element is optimized for energy efficiency, durability, and compliance with industry standards.

2. Custom Plant Design for Diverse Raw Materials Whether your distillery runs on molasses, grain, sugarcane juice, or other biomass, Rattan’s engineers tailor the plant design accordingly. Their flexible configurations allow clients to switch raw materials if needed — a vital advantage in today’s fluctuating agri-based input market.

3. Advanced Process Automation Rattan Industrial integrates PLC/SCADA automation across the distillation and utility sections to enable real-time monitoring, improved control, and minimal human error. This not only ensures consistent product quality but also reduces operational costs over time.

4. Quality-Focused Fabrication All equipment is manufactured using high-grade stainless steel, adhering to GMP and ASME standards. Components like distillation columns, heat exchangers, condensers, and receivers are designed for easy maintenance and long service life.

5. Environmental Compliance & Effluent Treatment Sustainability is a major concern in the distillery sector. Rattan provides integrated solutions for effluent treatment, bio-methanation, and evaporation, ensuring that your plant remains environmentally compliant and efficient.

Industries & Applications

Potable Alcohol Distilleries: For IMFL (Indian Made Foreign Liquor), country liquor, and premium spirits.

Fuel Ethanol Plants: Ethanol production for blending in petrol as per India’s EBP (Ethanol Blending Program).

Pharma and Industrial Solvents: Production of high-purity alcohol for industrial or medicinal use.

Rattan Industrial: Trusted Across India & Beyond

With a strong presence across India’s major liquor-producing states and growing international clientele, Rattan Industrial has earned a reputation for reliability, innovation, and strong after-sales support. Their in-house team of engineers, project managers, and fabrication experts ensures that every plant is delivered on time, within budget, and with exceptional quality.

Final Thoughts

For businesses looking to set up or expand their distillery operations, choosing the right technology partner is critical. Rattan Industrial India Pvt. Ltd. combines decades of experience, modern engineering practices, and a client-first approach to deliver turnkey distillery plants that perform under pressure.

Visit:- https://www.liquorbottlingplants.com/distillery-plant.html

0 notes

Text

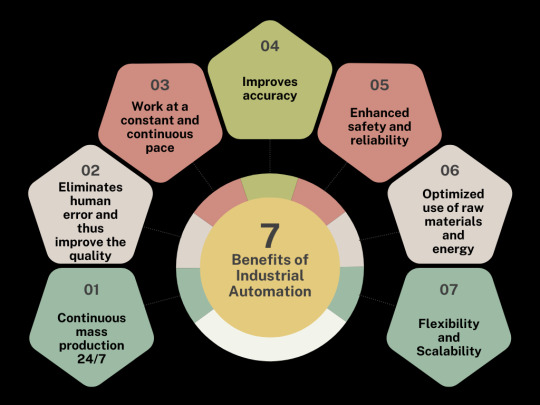

Industrial automation transforms industries by optimizing processes, improving productivity, and reducing operational costs. It replaces repetitive tasks with advanced technology, ensuring consistent quality and enhanced safety. With systems like PLCs (Programmable Logic Controllers), businesses achieve greater precision and control in manufacturing and other operations. PLC programming courses equip individuals with the expertise needed to harness these technologies and thrive in the evolving automation landscape.

0 notes

Text

Training Institute For Robotics In Pune

Welcome to Perfecto Robotics Institute, the leading Training Institute For Robotics In Pune. Our institute stands out for its complete courses and leading-edge facilities. Whether you’re a beginner or an experienced professional looking to advance your skills, we offer a number of programs to meet your needs.

To begin with, Perfecto Robotics Institute provides hands-on training from industry experts. Students actively participate in practical sessions, gaining a thorough understanding of robotics principles. Additionally, our instructors emphasize real-world applications, preparing graduates for diverse challenges in robotics.

Furthermore, our institute features state-of-the-art labs with the latest robotics hardware and software. This enables students to simulate industrial schemes and acquire practical experience in programming and operating robots. Moreover, our small class sizes encourage interactive learning and individualized attention.

What is the Training Institute For Robotics?

The Training Institute of Robotics offers practical training sessions where students can work and learn with real robots.

The Robotics Institute where students gain hands-on experience.

Benefits of Robotics Training:

Hands-on Experience

Skill Development

Career Opportunities

Innovation and Creativity

Industry-Relevant Knowledge

Collaborative Skills

Increased Efficiency and Productivity

Problem-Solving Abilities

Global Impact

Moreover, robotics training offers a wide range of benefits. We offer our students gaining practical skills to employment opportunities to foster innovation as well as support global technological advancement.

Robotics Institute offered courses:

Basic Industrial Automation

Advance Industrial Automation

Basic Industrial Robotics

Advance Industrial Robotics

In conclusion, Perfecto Robotics Institute is the premier Training Institute For Robotics In Pune, distinguished by its practical approach, advanced facilities, and industry-focused curriculum. Contact us to embark on a successful career in robotics. Explore our courses today and take the first step towards becoming a skilled robotics professional.

0 notes

Text

Basic SCADA programming - How can beginners get started without feeling overwhelmed?

Even a simple SCADA setup can control PLCs, connect RTUs, and provide clear visualizations. But where should you begin, and what should you avoid?

Full step-by-step guide here: https://maxelectric.vn/huong-dan-lap-trinh-scada-co-ban-cho-nguoi-moi-bat-dau-a155.html

0 notes

Text

Why is PLC programming used?

Have you ever thought about how enormous industries, industrial facilities, or even amusement park attractions operate so smoothly? PLCs (Programmable Logic Controllers) are a fascinating technology that holds the solution.

What is PLC programming?

PLC programming is the process of developing instructions for a specific digital computer known as a PLC. These controllers function as the brains behind the scenes, automating a variety of operations and jobs in companies, buildings, and even home appliances.

Why is PLC Programming Used?

Automation Simplified: By automating repetitive operations, PLC programming revolutionizes businesses. PLCs can conduct pre-defined sequences of activities instead of depending on human operators, making industrial processes quicker and more dependable.

Accuracy and precision: PLCs provide accurate control over machines and processes. They can accurately measure and respond to factors like temperature, pressure, and speed, assuring consistency in production and decreasing mistakes.

PLC programming provides engineers with the ability to simply alter and update control logic. This adaptability allows for fast alterations to match changes in production requirements or process enhancements.

Enhanced Safety: In industrial environments, safety is of the utmost importance. PLCs are configured to apply safety features like emergency stops and interlocks, which safeguard personnel and equipment from possible risks.

PLCs can monitor and diagnose operations in real time, providing vital data on performance and efficiency. This information assists engineers in analyzing patterns, identifying problems, and optimizing manufacturing operations.

PLCs may interface with other devices such as sensors, motors, and Human-Machine Interfaces (HMIs), resulting in a comprehensive and linked control system.

Cost-Effectiveness: PLCs are less expensive than custom-built control systems. They provide a dependable and standardized solution that lowers total implementation costs.

PLCs contribute to energy management by optimizing power use in processes, allowing organizations to save money on energy and lower their carbon impact.

Conclusion

PLC programming has transformed how industries and organizations work by automating and streamlining operations. These smart controllers provide accuracy, flexibility, and real-time monitoring, resulting in safer, more efficient, and cost-effective manufacturing. We may expect a smarter and more connected world as PLC programming drives the future of automation. PLCs' potential uses will only grow as technology advances, altering industries and enhancing our daily lives.

PLC training is required for working professionals to comprehend this. Training is required for a deeper understanding, and institutes such as DIAC in Noida are helping professionals maximize their utility for many years to come. PLC programming is at the heart of industrial automation, allowing for the efficient management and monitoring of a wide range of operations in manufacturing, energy, infrastructure, and beyond.

#plc training#plc scada training#plc scada training in noida#plc networking#plc scada#scada training#plc scada training in delhi#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses

0 notes

Text

Programmable Logic Controller Market Set to Hit US$ 17.2 Bn with Strong Demand from Smart Industries

The global programmable logic controller (PLC) market, valued at US$ 11.6 Bn in 2022, is forecast to grow at a CAGR of 4.7% between 2023 and 2031, reaching a market value of US$ 17.2 Bn by the end of 2031, according to the latest industry insights. This growth is propelled by a surge in demand for industrial automation, smart manufacturing, and increased integration of the Industrial Internet of Things (IIoT).

Market Overview: A programmable logic controller (PLC) is a digital computer used to automate electromechanical processes, particularly in manufacturing environments. These devices are integral to the efficient operation of assembly lines, robotic devices, and any activity requiring high-reliability control and ease of programming. With increasing adoption across automotive, food & beverage, chemical, energy & utility, and construction industries, the global PLC market continues to expand in scope and application.

Market Drivers & Trends

The rising trend of smart factories and Industry 4.0 is among the most significant growth drivers. Manufacturers are increasingly adopting automation to reduce operational costs, improve productivity, and enhance precision. PLCs play a critical role in this transformation by allowing control over complex industrial processes with minimal human intervention.

Additionally, the growing need for data-driven decision-making, along with advancements in machine learning and artificial intelligence, is leading to deeper integration of PLCs in industrial settings. As automation becomes central to production and operational strategies, the demand for PLCs is expected to surge further.

Latest Market Trends

One of the most notable trends is the shift toward modular PLCs, which accounted for over 68.2% of the market share in 2022. These PLCs are gaining popularity due to their scalability and suitability for large-scale, complex automation tasks. Modular systems offer higher flexibility, can handle thousands of inputs/outputs, and support multitasking environments—making them ideal for high-volume manufacturing operations.

Another trend is the miniaturization of PLCs, which supports their deployment in compact systems and small machinery, especially in consumer electronics and smaller automated units.

Key Players and Industry Leaders

The competitive landscape is fragmented yet dominated by global industrial automation giants. Leading companies in the PLC market include:

Siemens

Rockwell Automation

Mitsubishi Electric Corporation

Schneider Electric

OMRON Corporation

ABB

Panasonic Corporation

Bosch Rexroth Corporation

Delta Electronics, Inc.

Honeywell International Inc.

These companies continue to drive innovation through strategic partnerships, R&D investments, and product expansions to enhance their market share and global footprint.

Recent Developments

Crouzet, in December 2022, launched Millennium Slim, the slimmest PLC in the world, tailored for compact industrial applications.

In July 2022, OMRON Corporation introduced the CP2E Micro PLC, designed for smaller devices and capable of data collection and machine-to-machine communication. This supports low-cost automation solutions for small- and mid-sized enterprises.

Electronics Corporation of India Limited (ECIL) released its own PLC and SCADA software in May 2022, targeting industrial control applications in Indian manufacturing ecosystems.

These product introductions underline the market’s commitment to technological advancement and responsiveness to evolving industrial demands.

Market Opportunities

The expansion of material handling systems, especially in e-commerce logistics, warehousing, and food processing industries, presents substantial growth potential for PLC integration. In material handling, PLCs streamline storage, movement, and tracking—drastically improving throughput and inventory management.

Additionally, the increasing popularity of energy-efficient manufacturing and sustainability initiatives provides ample opportunity for advanced PLC systems that help monitor and reduce energy consumption across production lines.

Gain a preview of important insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=32672

Future Outlook

The future of the programmable logic controller market lies in enhanced interoperability, cloud integration, and edge computing. With greater reliance on smart infrastructure and connected devices, PLCs are expected to evolve into more intelligent, connected controllers.

The incorporation of AI-powered PLCs is expected to revolutionize industrial automation by enabling predictive maintenance, self-diagnosis, and adaptive process control. As PLCs continue to advance, their use will extend beyond industrial sectors into smart cities, transportation systems, and building automation.

Market Segmentation

By Offering:

Hardware: CPU, I/O Modules, Power Supply, Memory System

Software

Services

By Type:

Compact PLC

Modular PLC

Nano, Micro, Small, Medium, and Large PLCs

By Application:

Material Handling

Packaging & Labeling

Process Control

Safety Monitoring

Energy Management

Home & Building Automation

Industrial Equipment Control

By End-use Industry:

Automotive

Energy & Utilities

Food & Beverage

Pharmaceuticals

Construction

Oil & Gas

Semiconductors & Electronics

Regional Insights

Asia Pacific held the largest market share of 36.3% in 2022, led by strong industrial growth in China, Japan, South Korea, and India. The increasing demand for smart manufacturing systems and compact automation solutions in the region is expected to maintain its dominance through 2031.

North America, with a market share of 26.4% in 2022, continues to grow due to early adoption of factory automation and significant investment in smart infrastructure in the U.S. and Canada.

Europe remains a hub for automation technology innovation, with countries like Germany, the U.K., and France focusing on Industry 4.0 implementation across automotive and manufacturing sectors.

Why Buy This Report?

This comprehensive report offers:

Detailed market size, forecast, and growth rate

In-depth competitive landscape and company profiling

Analysis of key market drivers, trends, and opportunities

Region-wise breakdown for strategic decision-making

Porter’s Five Forces, value chain, and trend analysis

Insights into technological developments and their impact

Market segmentation for customized investment strategies

With expert analysis and forward-looking insights, this report serves as a valuable resource for stakeholders, investors, industrial engineers, and policymakers seeking to navigate and capitalize on the fast-evolving programmable logic controller market.

Explore Latest Research Reports by Transparency Market Research: 5G Smart Antenna Market: https://www.transparencymarketresearch.com/5g-smart-antenna-market.html

Solid State Transformer Market: https://www.transparencymarketresearch.com/solid-State-transformer.html

Interactive Display Market: https://www.transparencymarketresearch.com/interactive-display-market.html

GaN Epitaxial Wafers Market: https://www.transparencymarketresearch.com/gan-epitaxial-wafers-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

What You Will Learn in Industrial Automation and Robotics Courses?

Traditional manual processes have now transformed into smart systems that respond with speed and precision. From packaging lines that operate around the clock to robotic arms performing delicate tasks with surgical accuracy, the world of industrial production is evolving. And at the heart of this change lies a new kind of technical literacy, one built through Industrial automation and robotics courses.

But what exactly do these programs teach? And why are they so important today? Let’s explore what students really gain from this kind of education, and how it prepares them to thrive in tomorrow’s industries.

Foundational Engineering Knowledge That Matters

Before students can dive into robots or controllers, they need to understand the language of automation. These courses begin with essential principles: electrical theory, logic design, mechanical fundamentals, and system dynamics. Learners study current flow, sensors, basic circuits, and safety devices. They also explore control systems, how feedback works, what makes a loop stable, and how machines respond to various inputs.

Programmable Logic Controllers (PLCs)

Programmable Logic Controllers, or PLCs, form the core of most industrial automation systems. Unlike traditional relay setups, these compact computers carry out control tasks instantly by following logic sequences built by engineers. Students gain direct experience working with real hardware, learning to configure, test, and program PLCs using industry-standard languages such as ladder logic, structured text, and function block diagrams.

Courses focus not just on writing code but on solving problems: detecting errors, optimizing sequence flow, and debugging physical setups. Whether it’s running a simulated traffic light or managing conveyor timing, the logic must be precise.

Human-Machine Interfaces (HMI) and SCADA Systems

As machines grow smarter, the need for clear communication between systems and humans increases. That’s where HMI and SCADA systems come in.

Students learn to design interactive screens that allow operators to control and monitor processes, from pressure levels in a reactor to the speed of a bottling line. They develop layouts, manage alarms, create trend graphs, and set up data logging.

Equally critical is understanding SCADA architecture, how large-scale systems monitor multiple devices across facilities. These interfaces aren’t just dashboards. They’re lifelines. In high-risk or high-speed environments, the right display can prevent failure.

Robotics: Control, Precision, and Integration

Beyond sensors and switches, industrial robotics introduces a whole new dimension. These machines perform physical tasks with accuracy and consistency, from welding to material handling. In Industrial automation and robotics courses, students explore robotic motion planning, coordinate systems, joint movement, and gripper design.

Training includes simulation as well as real robotic arms. Learners program actions, define tool paths, and calibrate devices to respond to various scenarios. Robotics also demands a sharp eye for safety, understanding fail-safes, emergency stops, and risk analysis becomes part of the curriculum.

Sensor Technology and Instrumentation

In automation, sensing is everything. Machines need to detect position, measure flow, monitor temperature, or determine proximity, all without human input. That’s why students spend time studying sensors in depth.

They learn the theory and application of photoelectric sensors, limit switches, ultrasonic devices, thermocouples, and encoders. Courses often include wiring, calibration, signal processing, and sensor fusion techniques.

It’s one thing to install a sensor. It’s another to ensure its readings are accurate, consistent, and usable within an automation loop. A well-tuned sensing system is the difference between reliable automation and constant failure.

Drives, Motors, and Motion Control

Movement in automation is never random. Whether it’s a robotic arm pivoting or a conveyor transporting items, motion must be controlled, smooth, and predictable.

Students study various types of motors, stepper, servo, induction, and the drives that control them. They learn to manage speed, torque, and direction. Courses also explain PID control, acceleration curves, and how to prevent vibration or misalignment.

Practical lab work allows learners to connect motors, set drive parameters, and test results under different loads. These experiences create engineers who don’t just understand motion, they can manage it with precision.

Integration Projects: From Concept to Commissioning

Toward the end of most programs, students apply everything they’ve learned in a capstone project. This may involve designing an automated process from scratch, selecting hardware, building control logic, integrating sensors, and testing systems.

It’s not just a test. It’s preparation. It simulates real challenges, including incomplete specs, equipment failure, or changing project goals. The experience builds not only confidence but also the kind of problem-solving mindset employers look for.

Safety, Compliance, and Standards

No system, no matter how efficient, is worth endangering a worker’s life. That’s why safety is woven throughout every topic. They learn how to design systems that prevent unexpected starts, reduce hazards, and shut down when needed.

They also learn to assess risk, calculate safety integrity levels, and implement proper machine guarding. These aren’t theoretical concerns, they’re daily priorities in every automation role.

Final Thoughts

For anyone looking to step into a future-proof career, technical depth and adaptability are essential. Industrial automation and robotics courses offer both. They build an understanding of how machines function, how systems connect, and how processes can be improved through smart engineering. Whether you aim to be a systems integrator, controls engineer, maintenance lead, or robotics programmer, what you learn in these courses is more than skill, it’s your launchpad into a smarter, faster world.

0 notes

Text

Exploring EEE in Engineering: Subjects, Syllabus & Career Opportunities

Introduction

Electrical and Electronics Engineering (EEE) is one of the most dynamic and versatile branches in the field of engineering. It integrates the principles of electricity, electronics, electromagnetism, and computer systems to design, develop, and maintain electrical equipment and electronic devices. Whether it’s power grids, automation systems, or embedded circuits, EEE professionals play a pivotal role in shaping the technology-driven world we live in.

This blog serves as a complete guide to understanding the subjects in EEE engineering, the course structure, and the career paths it unlocks.

What is EEE (Electrical and Electronics Engineering)?

EEE is a core engineering discipline that focuses on both electrical systems (such as power generation, transmission, and motors) and electronics (like microcontrollers, signal processing, and embedded systems). It’s an ideal choice for students who are analytical, curious about how things work, and passionate about innovation.

Course Duration & Eligibility

Course Name: B.E./B.Tech in Electrical and Electronics Engineering

Duration: 4 years (8 semesters)

Eligibility: 10+2 with Physics, Chemistry, and Mathematics (PCM) + entrance exams like JEE Main, state CETs, or institute-level tests

Core EEE Subjects: Semester-Wise Breakdown

EEE curriculum is spread over 4 years and focuses on both theoretical learning and practical application. Here's a semester-wise overview of key subjects:

Year 1: Basic Engineering & Foundation

Engineering Mathematics I & II

Physics & Chemistry

Basic Electrical & Electronics Engineering

Programming in C

Engineering Graphics

Environmental Science

Workshops and Labs

Year 2: Electrical & Circuit Theory

Circuit Analysis

Network Theory

Electronic Devices & Circuits

Electromagnetic Fields

Signals and Systems

Analog and Digital Electronics

Electrical Machines – I

Simulation Lab, Devices Lab

Year 3: Core Technical Development

Electrical Machines – II

Control Systems

Power Electronics

Microprocessors & Microcontrollers

Transmission and Distribution

Measurements & Instrumentation

Renewable Energy Systems

Power Systems Lab, Embedded Systems Lab

Year 4: Advanced Topics & Applications

High Voltage Engineering

Smart Grid Technology

Electric Drives & Control

Industrial Automation (PLC, SCADA)

Elective Subjects (Robotics, IoT, Artificial Intelligence in Electrical Systems)

Final Year Project

Internship & Industrial Training

Practical Learning & Lab Work

EEE places strong emphasis on hands-on learning. Students gain real-world experience through:

Circuit design and simulation

Hardware testing and troubleshooting

Mini projects and capstone projects

Industrial visits and live projects

Coding for embedded systems using Arduino, Raspberry Pi, etc.

Skills You Gain in EEE

Strong analytical and mathematical reasoning

Hardware and circuit design proficiency

Knowledge of renewable and sustainable energy

Programming skills (C, C++, Python for microcontrollers)

Problem-solving and project management

Interdisciplinary collaboration

Career Opportunities After EEE

Graduates in Electrical and Electronics Engineering are in high demand across sectors like energy, manufacturing, automation, transportation, and IT. Common job roles include:

Electrical Engineer

Power Systems Engineer

Embedded Systems Developer

Electronics Design Engineer

Automation Engineer

Control Systems Engineer

Maintenance Engineer

Technical Consultant

Major recruiters include public sector undertakings (PSUs like BHEL, NTPC, ONGC), private MNCs (Siemens, ABB, Schneider Electric), IT firms (TCS, Wipro, Infosys), and startups in renewable energy and robotics.

Higher Studies & Certifications

Students often pursue postgraduate degrees like:

M.Tech in Power Systems / VLSI / Control Systems

MBA in Operations or Project Management

International MS in Electrical Engineering

Additionally, certifications in PLC programming, SCADA systems, MATLAB, or IoT applications can greatly enhance job prospects.

Final Thoughts

EEE is an exciting and future-proof engineering stream that opens up diverse opportunities in traditional and emerging industries. With a curriculum that balances theoretical knowledge and practical exposure, students graduate with the skills needed to power innovation and electrify the future. If you’re a student passionate about circuits, energy, and electronics, Electrical and Electronics Engineering could be your perfect career path.

Website:https://kce.ac.in/

Address:Myleripalayam Village, Othakkal Mandapam Post, Coimbatore - 641032, Tamilnadu, India

+91 82203 33750, +91 82203 33620 +91 422 2619005, +91 422 2619006

Mail id :[email protected]

#best engineering colleges in coimbatore#education#college#top engineering colleges#career opportunity for engineering students#eee#best electrical and electronics engineering college in coimbatore

0 notes